A family-run farm where grass, genetics and steady improvement deliver results year on year.

Walter Murphy is based in Carrick-on-Suir, Co. Waterford, where he has been farming since leaving school in 1977. He officially took over the reins of the farm in 1992 and has since developed a progressive dairy and beef enterprise built on grass-based production, clearly defined breeding goals suited to his system, and consistent year-on-year improvement.

Today, the farm operates very much as a family business. Walter farms in partnership with his daughter, Caroline, alongside a full-time employee, while his wife and three other daughters also play an active role during busy periods throughout the year.

Walter currently milks 140 spring-calving cows, targeting approximately 6,000 litres of milk and 500kg of milk solids per cow. Historically, the herd was predominantly British Friesian; however, over time Walter has transitioned towards a Holstein-Friesian type, with a target of around 70% Holstein influence. This change has been driven by a focus on improving milk yield and solids production while maintaining suitability for a grass-based system.

In recent years, Walter has adopted the use of sexed semen on his heifers to produce replacement stock and has found this to be a great success. He also selectively uses sexed semen on some of his top-performing cows, with the remainder of the herd bred to beef sires.

Grass is central to the system. Calving begins in mid-January, with cows typically turned out to grass by February 20th, weather permitting. Cows remain outdoors until mid-November, reflecting the quality of the farm’s grazing platform, which is located in a single block. This structure supports efficient labour use and low-cost milk production.

Walter is a supplier with Tirlán and has seen consistent improvements in performance year on year, driven by careful breeding decisions, strong management, and close attention to detail.

Alongside the dairy enterprise, Walter finishes approximately 220 cattle annually, including his own dairy-beef calves and around 80–90 purchased suckler heifers. In previous years, the farm finished up to 350 cattle; however, stocking numbers have since been reduced due to derogation changes — an issue Walter sees as a major concern for the long-term viability of farms across the country.

All dairy-beef calves bred on the farm are finished on-site. Belgian Blue is widely used across the dairy herd, producing high-quality cattle that consistently achieve R grades. “The Belgian Blue on the dairy cow is a great cross—super cattle to work with, that weigh well and kill well,” Walter explains. A Limousin bull is used for mopping up on the dairy herd, while Charolais and Limousin genetics dominate the suckler heifers purchased each year, selected specifically for finishing performance.

Purchased heifers — mainly sourced from Caherciveen Mart — are bought at 14 months of age or older, typically after second-cut silage in August. They are turned directly onto aftergrass, housed in October, and finished in April or May. All cattle are slaughtered under 24 months of age, generally between 21 and 23 months.

The farm targets 50% of suckler cattle grading U, with breed quality and genetics a top priority. The focus remains firmly on genetics, grass, and good overall management.

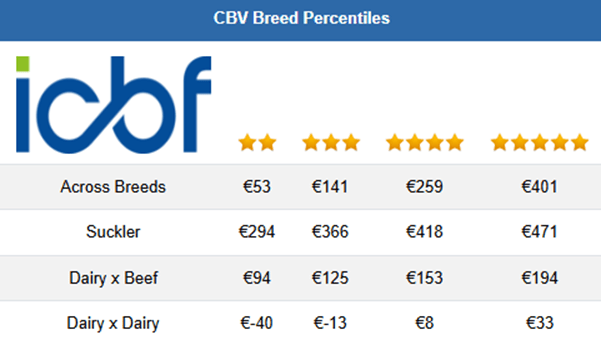

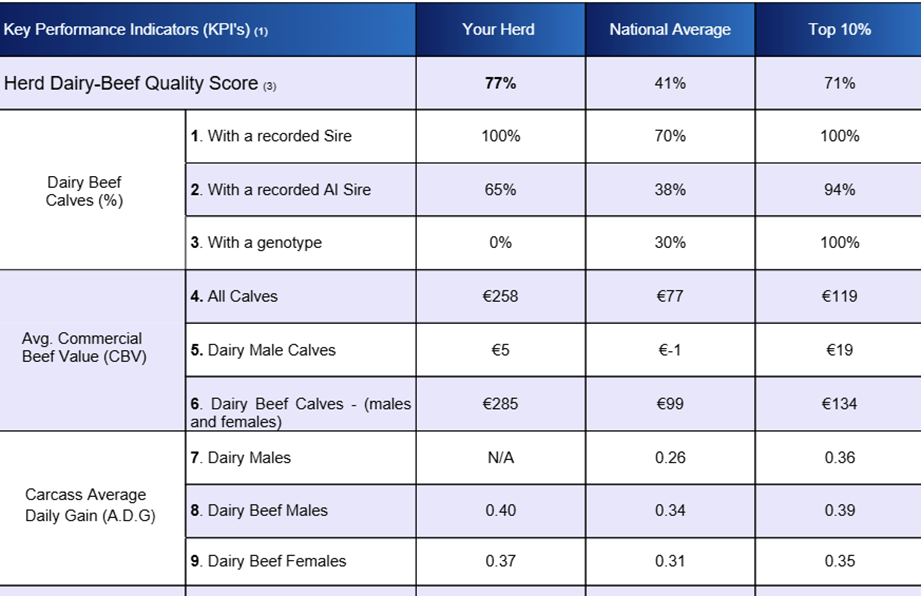

The quality and genetic merit of the cattle Walter is finishing is clearly reflected in the Commercial Beef Value (CBV) figures for the herd. When assessed against breed-type percentiles, the strength of the stock for finishing becomes evident. Walter’s suckler cattle have an average CBV of €424, with top-performing animals reaching €573.

Dairy-beef calves bred on the farm also demonstrate very strong CBV performance. To achieve a five-star rating on the Dairy x Beef CBV scale, animals must exceed €194. Walter’s dairy-beef calves have an average CBV of €268, while the 2025-born calves average €285, placing the herd in the top 2% nationally.

Animal health is a cornerstone of the Murphy farm. Comprehensive vaccination programmes are in place, including pneumonia and blackleg vaccinations for purchased heifers, while cows are vaccinated for leptospirosis, salmonella, and IBR. Regular dung sampling is carried out to monitor worm burdens, ensuring treatments are targeted and responsible.

The farm also participates in the Dairy Beef Weighing and Welfare Scheme, reinforcing Walter’s commitment to high standards of animal welfare and performance monitoring.

Labour availability is a concern for Walter, reflecting a wider challenge across the farming sector. To help ease pressure, automatic calf feeders are used, and he continually looks for ways to improve efficiency. Drying-off typically takes place from mid to late November, helping to manage workload during the winter months.

While the option existed to increase cow numbers, Walter has deliberately chosen to maintain a mixed dairy and beef system. “I like the beef business—seeing cattle coming on and improving year on year,” he says. “The diversity in the system keeps it interesting and spreads risk.”

After decades of work, 2025 has proven to be a good year for beef farmers. “These are good times, but they were a long time coming,” he said. His approach has always been to persevere and focus on improving every year — a philosophy clearly reflected in the performance of the Murphy farm today.